PARTS & ACCESSORIES

Quick RefeRence Guide

The Beckett AquaSmart is an advanced boiler control designed for use on residential and light commercial

boiler systems. All models include the option of enabling Beckett HeatManager™ dynamic temperature reset

that, when selected, provides up to 20% fuel consumption savings. The control includes a backlit LCD digital

display with touch pad to easily program temperature limits, differentials, and other advanced options. The

AquaSmart also has memory storage of system history for help with diagnostics and troubleshooting.

Temperature Ranges and Differentials

High Limit Setting Range: 100 to 240°F (38 to 116°C)

High Limit Differential Range: 5 to 45°F (3 to 25°C)

Low Limit Setting Range: 100 to 220°F (38 to 104°C)

Low Limit Differential Range: 10 to 45°F (6 to 25°C)

Factory Range Stops available - consult factory

Environmental Ratings

Storage Temperature: -40 to +150°F (-40 to +65°C)

Operating Temperature: -4 to +150°F (-20 to +65°C)

Maximum Sensing Element Temperature: 250°F (121°C)

Relative Humidity: 5 to 85% RH, non-condensing and

non-crystallizing

○

○

○

○

○

○

○

○

○

Technical Specications

Electrical Ratings

Input Voltage: 120 Vac - 50/60 Hz.

Input Current: 0.1 A + B1 + C1 + ZC

MAX Input Current: 20A (Reduce to 15A if optional

power switch is used)

24 Vac Thermostat Anticipator Current: 0.1 Amp.

Burner Current Rating (B1):

7600A (oil): 7.4 A at 120 Vac FLA; 44.4 A inrush LRA.

7600B (gas): 1.25 A at 24 Vac; 30 VA (total load).

Circulator Current Rating (C1): 7.4 A at 120 Vac FLA;

44.4 A inrush LRA.

Zone Control Current Rating (ZC): 7.4 A at 120 Vac

FLA; 44.4 A inrush LRA.

Do Not Use This Control in an Application that is Not Within the Ratings

Listed in This Section. Improper Control Operation May Result.

Electrical Shock, Fire, Explosion and Burn Hazards

This control must be installed, adjusted and put into operation only by a trained, licensed, qualied

professional or service agency in accordance with the National Electric Code ANSI/NFPA 70 (Canada CSA

C22.1) state, local codes and authorities having jurisdiction.

The installer must carefully read and follow the installation and service instructions contained in this pamphlet and in

the owner’s manual. Make them available to the equipment owner, so they can be kept for future reference.

Please refer to the AquaSmart Owner’s Manual for more detailed instructions and advanced

programming options.

Approvals

Underwriters Laboratories Recognition to UL353, UL1998 for U.S. and Canada

Page 2

Figure 1 - Getting to know the AquaSmart 7600 Series Control

OEM Installation: When replacing an OEM-installed

AquaSmart, consult the appliance manufacturer’s wiring

diagrams and instructions for additional information.

Retrot Installation: The AquaSmart can be used to

replace most standard boiler temperature controls. For a

cross-reference of compatible replacements, refer to

Owner’s Manual.

There are two basic methods for mounting the AquaSmart

to the boiler.

Sensor/Immersion Well Mounting – This is the

most common method. If the existing well is not

suitable for any reason, a standard design aftermarket

immersion well with the proper dimensions can be

purchased from a HVAC distributor. The AquaSmart

can then be mounted in the typical way.

Surface Mounting – This is sometimes required

and is part of the AquaSmart base design. The base

has adequate clearance built-in to accommodate the

temperature sensor lead exiting the back of the

control. A 48” extension cable (Pt. No. 52120) can

be purchased separately for applications where

needed.

1.

2.

Installation

B. Temperature Low Limit

In any mode or screen other than an OPTION sub-

menu, press the “LOW LIMIT” key.

The temperature displayed is the current setting.

Use the “▲” and “▼” keys to select the desired

setting. Tap the button to increase or decrease the

temperature by 1°, or hold it to increase or decrease

the temperature by 5° at a time. For cold-start

operation, turn the low limit off by pressing the down

arrow key repeatedly until OFF is displayed.

IMPORTANT: To prevent ue gas condensation and

reduce fatigue caused by thermal cycling on

conventional (non-condensing) boilers, the LOW

LIMIT set point should be 150° F or above.

NOTE: Boiler manufacturer’s temperature

requirements supersede this recommendation.

Press the “ENTER (RESET)” key. Conrm the

setting by pressing “ENTER (RESET)” again if the

value is correct, or “CANCEL (BACK)” if it is not.

C. Temperature High Limit Differential

In any mode or screen other than an OPTION sub-

menu, press the “HIGH DIFF” key.

The temperature displayed is the current setting.

Use the “▲” and “▼” keys to select the desired

setting. Tap the button to increase or decrease the

temperature by 1°, or hold it to increase or decrease

the temperature by 5° at a time.

Press the “ENTER (RESET)” key. Conrm the

setting by pressing “ENTER (RESET)” again if the

value is correct, or “CANCEL (BACK)” if it is not.

D. Temperature Low Limit Differential

In any mode or screen other than an OPTION sub-

menu, press the “LOW DIFF” key.

The temperature displayed is the current setting.

Use the “▲” and “▼” keys to select the desired

setting. Tap the button to increase or decrease the

temperature by 1°, or hold it to increase or decrease

the temperature by 5° at a time.

Press the “ENTER (RESET)” key. Conrm the

setting by pressing “ENTER (RESET)” again if the

value is correct, or “CANCEL (BACK)” if it is not.

1.

2.

3.

1.

2.

3.

1.

2.

3.

To ensure smooth appliance operation, the AquaSmart

requires a separation between the High and Low limits no

less than the greater differential plus 5°F.

For example: If the High Limit is set to 180°F, the High Diff

to 20°F, and the Low Diff to 10°F, the control will not allow

a Low Limit above 155°F (180°F - 20°F [the greater of the

two differentials] - 5°F = 155°F).

A. Temperature High Limit

In any mode or screen other than an OPTION sub-

menu, press the “HIGH LIMIT” key.

The temperature displayed is the current setting.

Use the ▲ and ▼ keys to select the desired setting.

Tap the button to increase or decrease the

temperature by 1°, or hold it to increase or decrease

the temperature by 5° at a time.

Press the “ENTER (RESET)” key. Conrm the

setting by pressing “ENTER (RESET)” again if the

value is correct, or “CANCEL (BACK)” if it is not.

1.

2.

3.

Basic Programming

Sensor Jack

Touch Pad

Clamping Screw For Sensor

Disconnect Switch (Optional)

TW/TR Terminals

Communication Port

Sensor Mount

Page 3

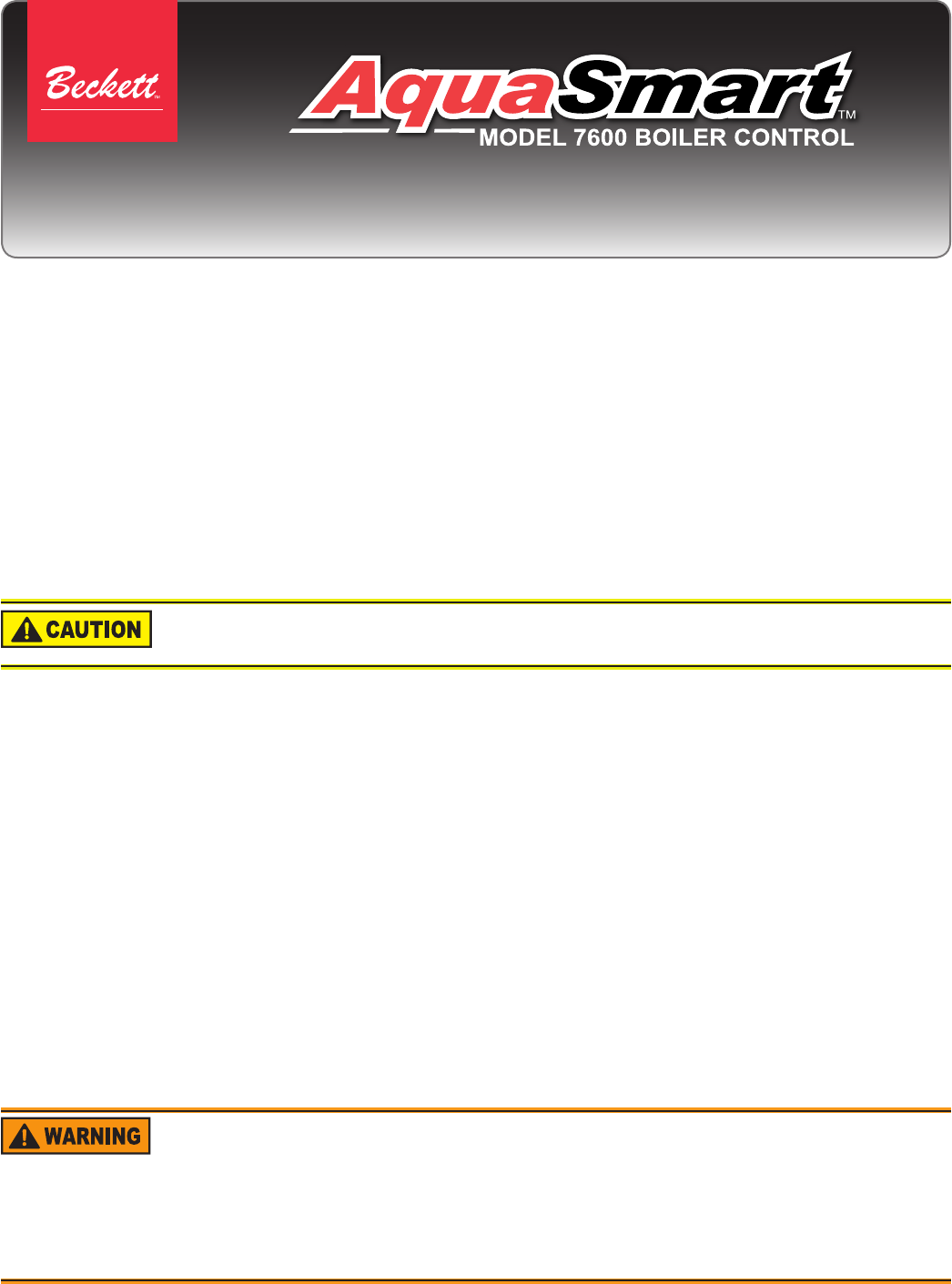

Figure 2 - 7600A/B single-zone connections with or without a tankless coil

Control Wiring:

1. Set “DHWP OFF” (default, see programming

section of the Owner’s Manual for further

instructions)

2. Set “C1 on TT” (default, see programming

section of the Owner’s Manual for further

instructions)

LOW VOLTAGE

THERMOSTAT

L2 L1 C1 C2 ZC ZR B1 B2

P1

CIRCULATOR

120 VAC

120 VAC

NEUTRAL WHITE

HOT

SERVICE

SWITCH

BLACK

7600A:

120 VAC BURNER OR

GAS IGNITION SYSTEM

7600B:

24 VAC GAS

IGNITION SYSTEM

TW

TR

WHITE

RED

BLACK

WHITE

SK10019

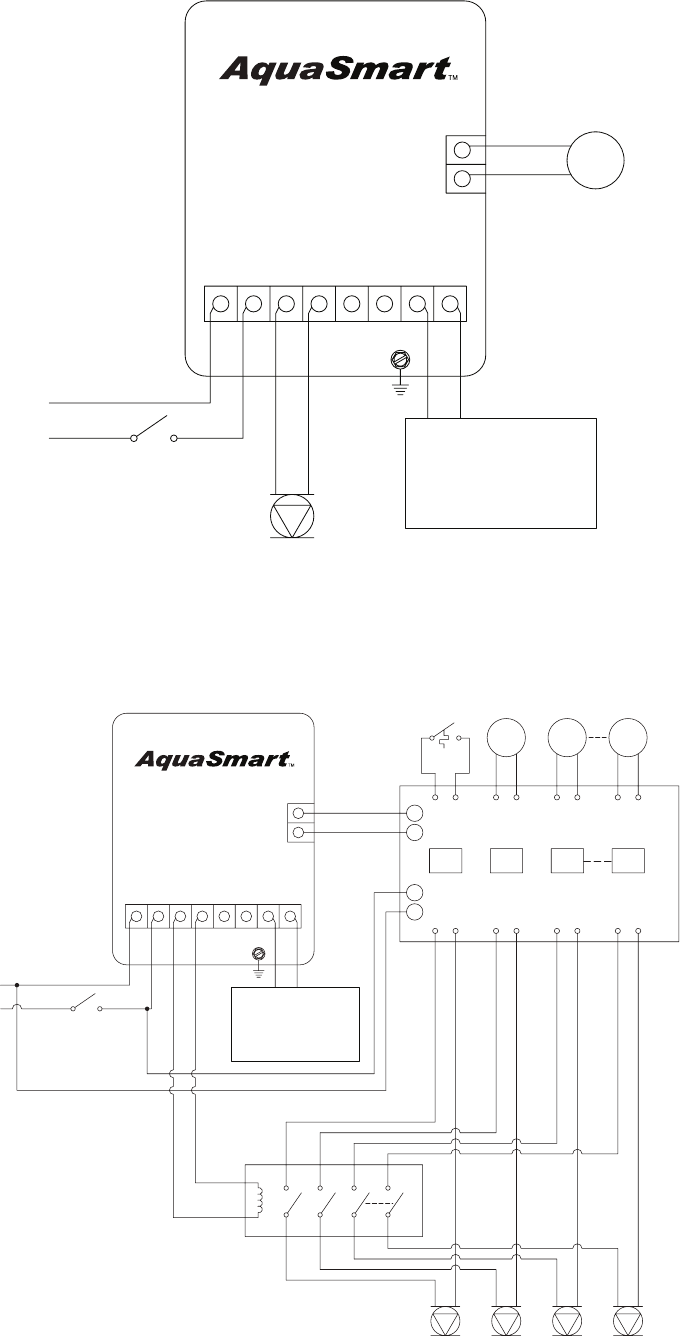

Figure 3 - 7600A/B multi-zone connections with Indirect Domestic Hot Water (DHW)

Control Wiring Option: Utilizing a Zone Panel

1. Set “DHWP OFF” (default, see

programming section of the Owner’s

Manual for further instructions) DHW Zone

priority will be determinedby the zone

panel.

2. Set “C1 on TT” (default, see programming

section of the Owner’s Manual for further

instructions)

3. Circulator-on delay will affect all zones.

Circulator-off delay will have no effect. If Circulator-

on delay is not desired, remove the n-pole contactor

and wire the circulators directly to the zone panel.

L2 L1 C1 C2 ZC ZR

B1

B2

TR

TW

SK10036

ZONE

PANEL

SERVICE

SWITCH

NEUTRAL

HOT

120 VAC

BLACK

WHITE

X

X

L1

L2

Z1 Z2 Z3 Zn

CIRCULATOR

120 VAC

P1

P2

CIRCULATOR

120 VAC

P3

CIRCULATOR

120 VAC

Pn

CIRCULATOR

120 VAC

n-POLE

CONTACTOR

120 VAC COIL

DHW

AQUASTAT

ZONE 1

LOW

VOLTAGE

THERMOSTAT

ZONE 2

LOW

VOLTAGE

THERMOSTAT

ZONE n

LOW

VOLTAGE

THERMOSTAT

END

SWITCH

7600A:

120 VAC BURNER OR

GAS IGNITION SYSTEM

7600B:

24 VAC GAS

IGNITION SYSTEM

Form No. 61757 Rev. 0, Printed in USA 09/09

PARTS & ACCESSORIES

USA: P.O. Box 1289

●

Elyria, OH 44036

●

Phone: 800-OIL-BURN (800-645-2876)

Canada: R.W. Beckett Canada, Ltd.

●

Unit #3, 430 Laird Road

●

Guelph, Ontario N1G 3X7

www.beckettcorp.com

Limited

WARRANTY

For Residential, Commercial and Specialty Burners

The R. W. BECKETT CORPORATION (“Beckett”) warrants to persons who purchase its Beckett burners from Beckett for resale or for incorpora-

tion into a product for resale (“Customers”) that its equipment is free from defects in material and workmanship under normal use and service

for 60 months from the date of manufacture for Residential Burners and 18 months from the date of manufacture for Commercial and Specialty

Burners. Residential burner models include: AF, AFG, AFII, NX, SF, SR and SMG. Commercial burner models include: CF375, CF500, CF800,

CF1400, CF2300A, CF2500, CF3500A, CG10, CG15, CG25 and CG50. Specialty burner models include: ADC, ADCP, ARV, SDC and SM. The

provisions of this warranty are extended to individual major burner components as follows:

a) 60 months from date of manufacture for all Beckett-branded major components, except for 12 Vdc components.

b) 18 months from date of manufacture for all non-Beckett-branded major components and Beckett branded 12 Vdc components.

c) 12 months from date of manufacture for all Beckett-branded tools, such as the GeniSys Display.

Note: Normal service items found to be defective upon receipt by the customer are covered by this warranty.

THIS WARRANTY DOES NOT EXTEND TO EQUIPMENT SUBJECTED TO MISUSE, NEGLECT, OR ACCIDENT: NOR DOES THIS WAR-

RANTY APPLY UNLESS THE PRODUCT COVERED BY IT IS PROPERLY INSTALLED BY A QUALIFIED, COMPETENT TECHNICIAN,

WHO IS LICENSED WHERE STATE AND LOCAL CODES REQUIRE, AND WHO IS EXPERIENCED IN MAKING SUCH INSTALLATIONS,

IN ACCORDANCE WITH THE LATEST EDITION OF NFPA NO. 31 OF THE NATIONAL FIRE PROTECTION ASSOCIATION, THE LATEST

EDITION OF THE NATIONAL FUEL GAS CODE (NFPA NO. 54) AND IN ACCORDANCE WITH ALL APPLICABLE LOCAL, STATE AND

NATIONAL CODES HAVING JURISDICTIONAL AUTHORITY.

Equipment, which is defective in material or workmanship and within the warranty period, may be returned for credit as follows: Beckett Burners,

Beckett-branded major components and non-Beckett-branded major components that came as original equipment on a Beckett burner or were

sold as a replacement part by Beckett should be returned, freight prepaid, to Beckett’s home of ce. Credit will be issued to the customer unless

the returned equipment is determined by Beckett to be out of warranty or damaged by user, in which case the equipment will be scrapped.

Note: Beckett is not responsible for any labor cost for removal and replacement of equipment.

THIS WARRANTY IS LIMITED TO THE PRECISE TERMS SET FORTH ABOVE, AND PROVIDES EXCLUSIVE REMEDIES EXPRESSLY IN

LIEU OF ALL OTHER REMEDIES, AND IN PARTICULAR THERE SHALL BE EXCLUDED THE IMPLIED WARRANTIES OF MERCHANTABIL-

ITY AND FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT WILL BECKETT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUEN-

TIAL DAMAGE OF ANY NATURE. Beckett neither assumes nor authorizes any person to assume for Beckett any other liability or obligation in

connection with the sale of this equipment, Beckett’s liability and Customer’s exclusive remedy being limited to credit as set forth above.

R.W. BECKETT CORPORATION

P.O. Box 1289 Elyria, Ohio 44036

Form No. 61545 R07